|

Home Updates Hydros Cars Engines Contacts Links ←Previous Next→ Contact On The Wire |

Off the Beaten Track

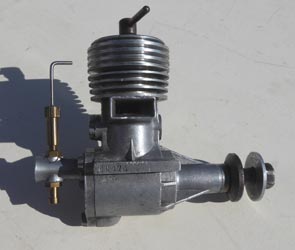

The Atomatic 5 - 5cc diesel

and AviominimaJohn Goodall and Salvatore Angeloni

I have always admired the beauty displayed in Italian engineering and it resulted in me acquiring a few Italian vintage motorcycles as well as several model engines and one early post WW2 example is the Atomatic 5cc shown here. Your editor saw it in my display case at the British Nationals last year and asked me to pen a few words. This was a problem as very little has been published in the UK on the marque and so I asked a friend in Italy Salvatore (Salvi) Angeloni, if he could help me and he sent most of what follows here and I am extremely indebted to him.

|

|

|

|

A selection of John's rare engines on show at Old Warden |

||

I knew Aviominima had distributed the engine and were based in Rome and that they had previously made a 4cc engine and that was the extent of my knowledge. The company was set up by Uberto Travagli born in 1920 while still a student of engineering at the Rome university. He was also Chief Editor of "Aquilone" (The Kite) the Italian Aeromodelling magazine. He set up Aviominima in the early 1940’s and traded from a shop in Via San Basilio in Rome. This was under Travagli’s home with just enough space for a small workshop. They sold plans, materials and modelling goods including engines made by a famous engine builder Elios Vantini of Padova who designed the Antares 4cc diesel made from 1942. Vantini was producing syringes commercially and what pushed him into making model engines is unknown, but good for us modellers? Only small numbers of the Antares were produced and today they are extremely rare, just like the Atomatic.

Travagli probably influenced by Vantini designed his first model engine the Atomatic 4 of 4cc in 1944, this had straight horizontal exhaust extensions and was followed in 1945 by the second version Atomatic 4 with down slanted exhausts. The help of his dearest friend Giovanni (Ninetto) Ridenti a very famous Italian Modeller was invaluable. The small workshop housed a lathe, milling machine, drilling machine and a flypress and employed a few craftsmen from the adjacent Breda Weapons factory, some of whom made parts in their spare time to supplement their income. The castings were produced by a foundry in another part of Rome.

The engine is a front rotary valve unlike the Antares which is a sideport and has an air control to vary the mixture another difference to the Antares. Bore is 16.5mm and stroke 20mm giving the tall appearance of the A 5. The fuel tank is situated around the front bearing housing with a screwed on cup giving the streamlined look in a very similar manner to the Antares as shown in the photos. Stylistically similar compression screws are used. The alloy casting is very clean and well finished seemingly made from a permanent mould. The Antares has a three lug mounting at its rear while the Atomatic has a mounting ring screwed into the rear housing with a central hole to clear the built in spring loaded "air bleed" engine cut-off. It has three screw holes to fix it to the bulk head of the model giving a very streamlined and clean overall look, very Italianate I would say.

|

|

| Atomatic and Antares mounting systems | |

In 1944 Travagli designed the first Italian Control line model called the "Swing" unique in that it had no bellcrank with the control wires directly connected to the elevator, it was powered by the Atomatic 4. It was a very elegant design, which sold well. The shop became a meeting point for all Roman Aeromodellers and a few American servicemen visited as well, among them John Zaic younger brother of the famous Frank Zaic. In 1947 the Atomatic 5cc was introduced again with the elegant down slanted exhausts as shown and a few of the Atomatic 10 probably of which only ten were made.

|

|

|

Aviominima Cistalia |

|

Shortly after this the shop closed for a few years and reopened in the early 1950’s, but production of the Atomatic engines had ceased and only other makers products were now sold including a few Tether Model Cars such as the Alfa Romeo Alfetta, Cisistalia, Ferrari 125 GPC powered by direct drive engines of 1-1.5cc. There was also a streamlined model in the catalogue for 2.5cc engines such as the Osam 2500, or Supertigre G20. The cars were made and assembled in the Aviominima workshop in very small numbers and like the Atomatic engines today are extremely rare and sought after.

|

|

|

Aviominima Ferrari |

|

|

|

| Aviominima Aerodinamica | ETI twinshaft by Turri and Ranzini |

Uberto Travagli never graduated in engineering from the University probably with too many distractions?? He died in 1993 leaving some of the most beautiful model engines ever made.

Byra and Vega cars with a selection of engines

Steve Betney

|

A rare Spanish Byra car and engine, which I bought on ebay. The engine was my main interest, as I was unaware that Byra had made any car engines, I only knew of them from their 2cc ED Mk 2 "copy" and a 1cc ED Bee lookalike (an example of which I've been looking for to add to my ED + replicas collection for decades). This 4.4cc car engines is crammed into a version of the Cox Champion car which they OEM'd from them. The main difference is the rather poorer quality of the car castings (possibly as a result of a knock down price, may have been manufacturer's sub standard rejects?), and the absence of the Cox etc lettering cast on the base pan bottom, which is totally plain, must have been specially cast as the lettering has not just been ground off. The engine is quite well made, and has only one driven shaft, the other being freewheeling. I will send more pics when the restoration is complete. The drive tyres are in good condition, the front car tyres were totally beyond redemption. |

|

Vega from Antony in France produced a whole range of modelling items including five types of motor from 1.5cc to 30cc, twenty car models, either finished or for the home constructor, ten sizes of wheel and tyres along with fuel and accessories. The company also advertised that they could supply nitro methane. The 1954 'D Type' Jaguar was available in two sizes, a 5cc from 1955 and a smaller 0.9cc about 1959.

|

|

I made a Vega Jaguar D Type many years ago from a set of JDRParis castings and was unbelievably lucky enough to get hold of an original and new Vega 0.9cc twinshaft engine shortly after that from Michel Molinie to put into it. About a year ago I got a set of original Vega D Type castings in poor condition from ebay Spain, and the current lockdown has had me at work on these recently. I decided to transfer the original Vega engine into the original castings and I have some tyres and wheels that I think are original Vega items (not the same/so clean as the other sets of repro Hungarian 35mm Vega tyres and wheel hubs which I have), to put a nearly totally original car together, the only thing missing was the back axle casting. No chance of ever getting another Vega 1cc twinshaft, so I set about researching other suitable period 1cc diesels to use. |

The Vega is a very compact front rotary engine with a very short distance between the centre line and the back of the prop driver face, and much research revealed that a 1956 Barbini B38 Mk 1 1cc and possible an Aquila Baby 1cc would match this, so as I had a nice unrun Barbini to hand, a lovely engine, this was used. Alan Knight turned it into a twinshaft (both shafts driven) to my drawings, and it fits exactly in the car. See Alan's article below for more photos of these conversions.

|

Sadly I have had to butcher the Barbini by removing both mounting lugs to fit in the car, a thing I really hate doing to any nice engine, but it was necessary. The images were taken before I did a final trial fit of the Barbini in the repro Jag castings, when I found that the upper lug fouled the top casting so had to be removed too...… Final paint jobs are all that is now needed to have these two little Jags finished. |

|

|

An interesting little reed valve 1cc car engine came into my possession a while ago, and this is an example of the North London Model Car Club (NLMCC) design intended for model rail cars in the early 1950s. I suspect that this is the particular example shown in Mike Clanford's engine book, having been through a number of hands over the years. It is a fairly well made little engine by an amateur model engineer, but needed a fair bit of sorting out. The con rod was filed from soft aluminium and had oval big and little ends as well as a twist, and the piston had a hairline crack from the gudgeon pin hole to the skirt, though compression was fair. I found that an ED Baby steel con rod was an exact replacement fit, surprising as 0.46cc versus 1cc capacity is a big difference, the NLMCC being very over square.

|

A new piston and rebore had it all better than it had ever been, and it runs well now. No construction drawings exist for this engine as far as I have been able to research. I imagine that the crankcase castings were produced by one of the Club members for sale to others to make their engines from, but the lugs are not their best feature, and remain undrilled and unfinished on this engine. |

|

|

A Black Panther and other car related projects

Alan Knight

|

One of the early entrants into the market for specialist tethered car motors was the Black Panther Engine Co from Los Angeles, the hot bed of specialist engine builders. The engine was advertised with some pretty wild claims that played on the name and was designed specifically for cars or boats. J L Engineering of Santa Monica, amongst others, supplied a conversion kit that allowed a long torque tube and a bevel gearbox and axle unit to be attached directly to the motor. This did involve replacing the entire crankshaft, integral flywheel with the longest shaft ever fitted to an engine, as noted below by Alan. In discussions with John Goodall he suggested I sent you a couple of photos of a vintage Black Panther tether car engine I have just built from castings for a pal. It is a impressive looking device - probably better suited as a doorstop than a tethered car as it is a seriously heavy bit of kit with a crankshaft nearly 8 inches long (fortunately with several bearings supporting it along its length). |

|

Setting the points would be a nightmare as you would need to remove the axle, transmission tube, guess the gap and reassemble before doing a continuity check to see if the points are working, I would suggest the designer was not gifted with a practical mind….. I think the castings for the case and diff housing came from Don Sohn along with some very dubious drawings but despite that I think it may run as the intake, transfer and exhaust timing is sort of OK and the compression is very strong - probably easier to run it as a glow considering the points issue. The exhaust manifolds could do with a polish but I think I will leave that for the owner to do - I’ve had enough of it!!

|

|

|

| Integral flywheel housing | Myriad of parts | Handsome but short lived |

Further to my earlier comments: As I have some level of mechanical sympathy I have not yet plucked up sufficient courage to try to turn the motor over via a wheel. The piston liner fit is excellent and the bevel gears are shall we say trivial (the spur on a 0.187" diameter section of the shaft). For initial starts it may be best on a loose glow plug to lessen the loads on the power train. Without the tube and axle assembled the motor feels very nice and springy but the drawings don’t give any viable dimensions for the combustion chamber so the ratio may be high - perhaps I should make a few shims and pass them to the owner!

|

|

| Very long crankshaft | Superbly engineered replica |

The Black Panther was claimed by the manufacturers to be 'Screaming streak of fury', Vicious and diabolical', 'Deadly to all competitors', 'Absolutely the hottest piece of iron to ever hit the track'? The company also made great play of the 'completely enclosed fly-wheel and timer' that Alan comments on.

If anyone is interested I have quite a lot of photos of the build and anyone is welcome.

|

|

| Barbini B38 MkI twinshaft conversion | Allbon Dart converted to a twinshaft |

Back in the 90s, Ivan Prior built a batch of twinshaft motors based on PAW components. A few years later, Tony and Gig Eifflander built just two twinshaft motors as a commission, based on their 2.5cc TBR engines. Alan has built this current batch on the earlier crankcases, which have been enthusiastically pursued on eBay or by private buyers.

|

|

| Four ball races in this mini ETA | Batch of PAW based twinshafts, 1.5, 2.5,3.5cc |

Another ‘gem’ is discovered

One of our most long established adages is ‘we knows what we know’ and implicit within that is that there is even more that we don’t, which is where the combined knowledge of the car, engine and boat community comes into its own. Last month we related how a ‘box of bits’ from the Lee collection turned out to be Jim Dean’s European Championship winning Dooling Arrow, but that was not the end of the surprises that emanated from that source, and yet again, it was some months before the importance of it came to light.

|

Amongst the car items was a very dirty and unidentified pan with a spur mount, axles, wheels and a set of unused and unusual, treaded tyres, a good start for a project and duly advertised, along with the remainder of the cars. As John Goodall relates below, two things then occurred almost simultaneously that changed the whole complexion of this find. The buyer pulled out of the deal, and John Lorenz emailed to say that the pan was in fact a Melcraft, not a name that immediately sprung to mind, although there is a Melcraft 29 motor in Clanford’s tome, so it was off to the shelf with all the American references to see what could be found? It was not until the ‘coffee table books’ were consulted that anything came to light. Ames has an exploded drawing of a car, along with an example on non-standard tyres, and Zausner an example with original ‘Champion’ V tread tyres. |

|

The company that produced the Melcraft was based in Saginaw, Michigan, run by two people; both conveniently called ‘Mel’, Mel Scmidt and Mel Blumlein. Their business was originally in building outboard motors before producing the model aircraft engine and finally the tether car. Production of the car lasted little more the one year around 1946. The 10cc sized car was sold as a chassis or with a carved balsa top to be finished by the purchaser. There is mention of a metal top becoming available, but as of yet, no one has ever seen one of these. Other than this, not a lot more is known about the Melcraft, apart from the claims in the Zausner book that there were probably only about ten complete cars sold, although this is also believed to be far from accurate. That at least five of them are known to exist, would indicate that actual production was far more extensive?

John Goodall continues the story

My son Paul who took over Barton Model products a few years ago now, obtained a large collection of model car related material the collection of the late Jim Lee. It included over one hundred engines in total, with vast amounts of engine spares including Dooling, McCoy and Hornet etc. There were car kits ranging from a John Sanderson reproduction, a virtually complete car kit down to all the Dooling 61 engine components, to fuel tank and tyres a bargain at £650, less than half price and the buyer expected a discount too?? The other end of the spectrum were cast chassis and body sets, including Oliver bodies that sold very quickly. Over hundred new useable tyres with vast amounts of literature, car drawings and magazines most of which are still available? A visit would be useful for this maybe, if any of this is of interest? Please arrange a visit as we are not always there.

|

Among the car stuff was this 10cc rolling chassis (right), which we did not recognise and we listed at just £250 with unused engine mount and new tyres. It sold to a buyer in USA, but the agreed sale was not paid for and in the mean time our enthusiastic friend also from USA John Lorenz identified the chassis as a Melcraft, a rare American car kit sold complete with wooden body now missing. I thought it might be more worthwhile for Paul and BMP if I made an alloy body for it and sold it as a complete car, ready to run. John Lorenz kindly sent some information and pictures of his original car to show what the body should look like and I mused that it should be fairly straightforward to make a similar and more pleasing body outline in hand beaten aluminium alloy, so I set to. |

|

The main forward part of the body could easily be formed from a piece of 1/10 inch alloy, chosen for stiffness, and bent into a hoop over suitable metal bars of similar diameter to the finished form and held in the vice, done by hand allowing for the reducing section towards the front. I could form a flare in front of the cockpit opening over a curved former using a large round metal bar offcut hammered down to get a nice curve. I made up wood formers for the nose and tail end and quickly determined the tail would need to be made in two pieces welded down the middle. The nose could be a one piece forming. I initially used 1/16 inch, 16g soft alloy, but found it was too flimsy in this body size, both for the nose and tail pieces. I therefore opted to use 1/10 inch alloy and hoped by judicious annealing I could form it on the wood plugs I had already carved to shape. I made an alloy filler for the rear of the chassis to make it rounded rather than the flat end, As I knew beating the tail shape would be extremely difficult to form if left with the flat. This makes for a much more pleasing shape too, even if not original?

|

|

|

| Body and scuttle as formed | Rounded rear end | Pan and body before welding |

My welder "Mash" from Long Eaton near Nottingham had previously told me how he assesses the annealing temperature of aluminium with a piece of soft wood, which is wiped over the surface as heating commences. A black line is evident when the correct temperature is reached, a little more heat applied removes the black line and it can be allowed to cool ready for more forming. I used to use soap, but this leaves a dirty line difficult to remove. I managed to form the new parts fairly easily and matched the parts to fit the others and the chassis outline ready for welding. I cut an oval hole in the nose forming and drilled holes for fixing the Dooling "F" type grill which I obtained from USA. I added an inset stretcher plate front and rear for securing the body top to the chassis using captive rivet nuts in these plates. A back rest at the rear of the cockpit was added to further increase rigidity and appearance. A headrest fairing was hacksawed and filed up to a streamlined shape from alloy bar and three holes tapped to secure it to the body tail end from the underside.

|

|

|

| Filler at front and rear | Modified rear end with headrest | Dooling F grill |

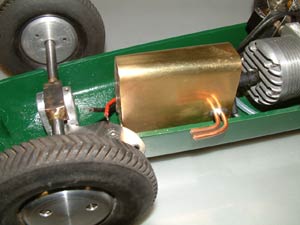

John Lorenz had mentioned he had once owned a Melcraft (below) which was used in a model shop window display near his home and actually built by the two Mels and he had fitted it with a Hornet 60 engine. I took one of the Jim Lee collection replica Hornet 60’s which was brand new, and drilled and tapped the engine mount for it and made the spur gears from a couple of gears I had previously wrongly ordered. These were fortunately much thicker, so I was able to cut these into two and make two pair’s from them.

|

|

|

| Original and pristine Melcraft with Hornet 60 motor | ||

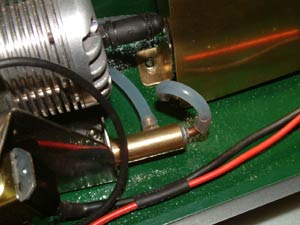

I made a combined fuel and ignition cut out from alloy and stainless steel, with the fuel cut off made from brass bar and steel piston with the design help of our own Hugh B. The fuel tank was bent up in brass sheet and soldered, complete with vents. Tether brackets to the original pattern were made in stainless steel and retained using existing tapped holes in the chassis. Some holes from previous use needed filling which I accomplished with Technoweld, and the intake blister I made over the end of a panel beating hammer to cover the Hornet venturi, secured likewise.

|

|

|

| Ignition arrangement | Plunger style fuel 'knock off' | Fuel tank with filler and breather |

After welding, final adjustments were made to the body to correct for any distortion in alignment with the chassis. Satisfied, I took it to Dumelo’s in Burton on Trent for stove enamelling in British Racing Green and I was pleased with the result. Final assembly included making a paxolin mount for the Smith ignition coil that I mounted vertically at the rear of the engine mount as space at front and rear ends of the chassis horizontally were stymied by the body retaining plates, which in hindsight I had made too large. I installed the wiring with space for the battery up forward, adjacent to the fuel tank. I think the result is a desirable and uniquely rare car, which is like no other Melcraft in durability terms and should now be saleable. Indeed it is now for sale, contact details on Market Place page.

|

|

|

| Hornet 60 | From a box of bits to completed Melcraft | |

©copyrightOTW&contributors2022