|

Home Updates Hydros Cars Engines Contacts Links Contact On The Wire |

Too much time to ponder, a lockdown saga?

As one of the longstanding hydroplane drivers used to ask during an evening round the campfire, do you want a story or a saga luv? Inevitably it was a long and involved tale, suitably embellished along the way that would keep us amused well into the night. What follows might not provide such a degree of amusement as it is reflecting on a quite extraordinary twelve months that shows every sign of not being over yet?

2020 did not start too well, with funerals of two fellow enthusiasts in quick succession and deteriorated progressively as event after event was being cancelled, even before the first lockdown was imposed. Ironic really as we were better prepared than ever before, knowing that it was going to be a busy season. In the end, it was cancelling bookings and trying to get refunds that kept us busy and the only mileage we did was on foot with our allowed exercise each day. One aspect that had not been anticipated was that three sessions of lockdown, and a period of very restricted activity in the summer would allow almost unlimited workshop time, imagine even suggesting that previously? Yet, a year on and that was what transpired, and not a guilty conscience for the time spent at the bench.

With Covid 19 not even having entered our lexicon and knowing how many trips and events were planned, I had started work as soon as the previous season had ended to ensure that everything was up to date, completing all the routine maintenance, preparing the cars and boats, even making up the new bridles. This included putting the 10cc Denneler on a diet to get it down to class weight with the new 5mm bridle, sorting out the massive bodge that had been wrought on the crankshaft and bearings of the ‘fast lady's’ aged Swedish 1.5cc car and some remedial work on my Class 3 CMB that persisted in shedding its flywheel at every given opportunity.

|

There is a continuous ebb and flow of projects in the workshop, although in itself that is a grandiose term. I can identify myself with such luminaries as Ian Moore and Jack Gascoigne, along with all the others that used to appear in ME having no garage, shed or dedicated workshop area yet produced remarkable work with the most limited facilities, not that mine is as remarkable. Tethered car or boat projects never come neatly packaged with all parts needed, neatly arranged, so the advancement of any particular project is entirely dependent on sourcing original parts or suitable alternatives, and if neither are to be found, making something appropriate. The lack of a body had held up completion of the last project that the late Dick Roberts was working on before ill health forced him to sell up, but as if by magic, John Goodall appeared at Peter Hill’s with one that looked about right and indeed, did fit, so that was another stalled project completed. |

|

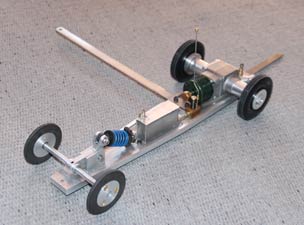

As the days shortened this was the state as just four possible projects remained on the shelf for the entire winter, all missing vital elements. The Salomon Killer car described previously needed an engine, but again John Goodall came to the rescue so that was back on track. A Redfin based car for Buckminster was a rough plan lurking in the back of my mind whilst two of John Goodall’s pan and body sets were just that with nothing to put in or on them, more than adequate to get through a normal winter, although six cars in total over four months might seem a tall order to some?

|

|

|

| Gary Barnes Railton, Yellow Jacket power | The 'Killer' | 'Scrap Box Special' |

Well, unlike a steam loco that can take anything from 1,000 hours to thirty years and still counting to complete, my engineering instructors instilled in us all a combination of speed and accuracy that I have maintained, although speed is now a relative term with a Unimat lathe and equally small Emcomat mill. The speed of production still comes through doing all the thinking at other times so that by the time I am at the bench I have a pretty good idea of what I am going to do, even to the extent of having a drawing, or more likely a very rough sketch. Some may find this hard to understand, but as an engineering student, our tutor used to involve us in all sorts of competitions that involved design, methods of production and speed of production. On one occasion he procured enough Stuart Turner 10V casting sets for the whole group and challenged us to see how quickly we could have one completed and running. He went home on Friday evening and by Monday morning; most of them were finished, actual time a shade under 18 hours, and that included a coat of paint and some lining.

|

A set of replica 2.5cc ZN body shells presented a similarly lightweight challenge. The Eureka transplant described in a Track Day Special released the PAW twinshaft for reallocation to this car where the most difficult job was drilling the fixing holes in the pan to match up with those in the mount, as the intake side of the engine is longer than the slave side. There is a drastic shortage of wheels and tyres at present, but the postal service from Latvia is superb so a quick call to Pavel and these were on hand. So, less than four days later and undercutting the 10V by nearly four hours in workshop time it was painted, and it is difficult to see how I could have spent any more time on it? The 5cc ZN was a bit more time consuming, just as well given what was transpiring. The only real difficulty with this car is that the top of the body is in two pieces with the front half welded on permanently. |

|

This means that holes have to be cut in the sides of the body to finangle the axle through and this is a drop axle so it has to be attached to a mount with absolutely no way of marking anything out accurately. The originals were all pre drilled as were the supplied axle and mount. I have seen one original ZN where the owner became so frustrated at this process that he cut monster holes for the axle to slide straight through in one piece. Probably the longest job on any car now is the tank but with a Broadbent folder and a set of mini benders it is a doddle, unless of course it is tapered in two directions and has curved sides as well, but I will come to that later.

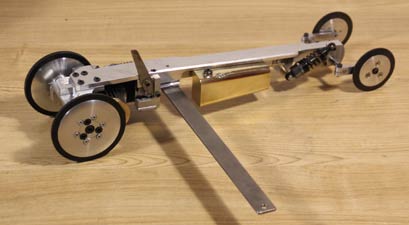

As related in a past Retro Reprint, standing for eight hours a day sticking packets of giblets up chickens bums or invigilating exams for five hours allows plenty of thinking time, so by the time the second ZN was complete the design of the Redfin was clear, even having done a bit of geometry for front suspension. Observing some of the earlier antics of twinshaft cars I decided to make the chassis much longer and then I added a bit more for luck. Front suspension with a damper was essential and then how to make a chassis that was rigid enough yet gave enough ground clearance? Now having said that I work fast, that does not mean that I take an easy way out, in fact often it is the reverse as I will often look for a more complicated solution if I feel it is more effective, elegant or in keeping or just plain perverse. Hence the Redfin car started out as a 8mm thick piece of aluminium plate milled out to just 4mm with a ball nosed cutter to provide sufficient webs and ribs. Now, if a ZN is quick, a plate chassis twinshaft is even quicker, partly because holding it for drilling, tapping or machining does not require any ingenious or time consuming set-ups. Now I have to own up to my bete noir, body work, I hate it, don’t have the facilities or materials, anything remotely smelly has to be done outdoors so relies on fine, warm and windless weather, not unduly common in this neck of the woods. So, unless I can do it in balsa or metal it tends to get left or sub contracted. As our diesel fuel is a bulk can that resides at Gt Carlton there was no chance to see if the motor would start, although most reports seem to comment on how easy it was, but the storm clouds were gathering.

|

|

|

| Replica 2.5cc ZN PAW twinshaft | Replica 5cc ZN ETA 29 | Redfin based Buckminster car |

Our first 10-day event in France had already been cancelled by the time we headed off to the FEMA car inspection and registration day, and as we are all too well aware, a week later we were into Lockdown 1. Suddenly, there were another three months of uninterrupted workshop time and very little on the bench. The daily exercise route did occupy a couple of hours a day, I know it was supposed to be just one but in the course of the three months we walked over 500miles, the car by comparison moved not an inch. Now desperation was setting in and the search for parts and possible projects gained momentum, was there anything at all left in the scrap box? The prevailing situation and results of the delving resulted in the Wasp like creation was described in the ‘Lament from a Lockdown Workshop’ and then a series of coincidences had parts arriving from all directions. Sadly, most of these were from the collections of our departed colleagues, being sold off, either on ebay or via personal contact, but oddly, one was a more or less complete car that I had sold many years ago and was able to buy back off ebay for much less than I had sold it for originally, so this became a donor for the ZN 5cc.

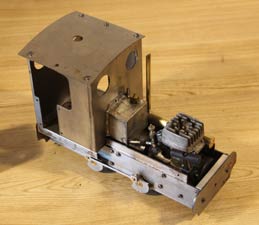

Prior to the first lockdown period I had been having long conversations with Peter Hill who had been tasked with disposing of the late Keith Bragg’s entire collection and workshop. Most of the complete cars, trains and a good many collectable engines had already gone as they represented significant sums, but what there was left were a large number of part completed and odd collections of items that had been earmarked for projects, but never got much beyond that stage. Only one of these was a tethered car, an Auto Union that had not progressed further than a body and a selection of bits, so that was added to my box awaiting collection, as were a selection of books and magazines by the hundred. Peter’s calls were prefaced with an announcement that ‘I’ve just found----- and put in your box thinking you might be interested’. Amongst these was half a Dutch, live steam tram, a couple of Bowman boats, one in need of extensive renovation and a selection of bits for an IP, electric powered diesel shunter. Not at first glance of great interest, but what is not widely known is that as well as his foray into tethered car items in the 1990s, Ivan Prior’s prime business was kits for model locomotives, railcars, carriages and more. At one stage he produced a range of live steam locos and other industrial locos. For a short while he manufactured a small diesel shunter that had an OS 10 providing the urge and it was a replica of this model that the odd parts were for as well as a large bundle of photos of the original, so in the box these went as well.

|

|

|

| Diesel (glow really) shunter | Two exhausts? | Dutch steam tram |

Readers may wonder at this assortment, but with a dearth of specific car material then boats and trains are never far away as an interest, so as soon as restrictions allowed, it was a day trip to Gt Carlton and a car full of goodness knows what? Not really part of this story, but these did keep me occupied for a while as the techniques, materials and steam had not been explored for many a year, but here a few, very lucky quirks of fate and coincidences, came to the rescue. My collecting and building has very much concentrated on British cars from the 40s and early 50s, primarily because that is what plans, parts and renovations projects are available here. From the late 50s until 1979 there was no British involvement in international tethered car racing, so no examples of cars or parts from that period made it to the UK, yet as a ‘racing man’ it was this period of development that fascinated me.

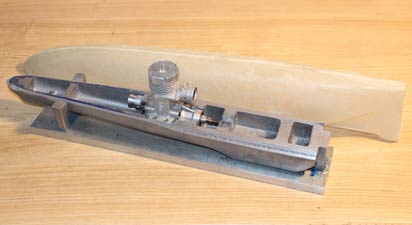

In 1960 cars had wheels outside on almost totally rigid axles, and were of American, proto style with side exhaust engines. Ten years later it was streamliners with tuned pipe, rear exhaust motors, wheels inside the body and full suspension front and rear that were the norm, plentiful abroad, but again almost non existent here. In a conversation with my mentor in Switzerland he told me of a car that his father had bought in the 1960s with the intention of turning it into a tuned pipe car, but had never got roundtuit, would I be interested? A deal had been agreed but the cancellation of our Spring Tour meant that it could not be collected, but in a magnanimous gesture he said that he would mail it and hope it would get through customs. Remarkably, and despite the difficulties with the postal system at the time, the package arrived, along with a period MOKI S5. I had made the decision previously to keep it as a side exhaust motor, so game on.

Faced with a project like this where no plans exist and everything has to be fitted round what is already there it is a trawl of our archives and t’internet’ to see how similar cars have been built. What was obvious was that there was not a lot of room for anything, especially as it all had to be enclosed by a speed cowl type body, prevailing at the time. Not only that but there was a dearth of holes in the pan so all the additions had to match up with these. A quick measure of the crown wheel that was already fitted gave me a module of 1.5 and by a stroke of luck in the spares box was a pinion of the correct module and angle, result. Short work to make a collet and re-purpose an existing flywheel, but with no facility to run a Unimat in reverse, getting a good fit relies on a bit of trial and error. A trial fit of the motor revealed something extremely odd that took some figuring out. For some entirely and unknown reason, whoever had machined the pan originally had set the drive side bearing far deeper into the ear than the other side by nearly 1/8" offsetting the crown wheel by a similar amount. This meant that the engine would have to be on the skew with the gears meshed properly, couldn’t be right, could it? Set up the pan on the mill and sure enough, the mounting holes for the motor and the cut-out for the crankcase were machined at an angle, so this was the way it had always been. It would have required much welding and re-machining to rectify this, so that is how it is, gears mesh at a slight angle but run smoothly enough.

|

|

|

The time consuming bit was the fuel system and in particular the knock off. In the 60s there were were variety of devices in common use, the old fashioned rotary one, tube crushers and spring loaded piston style, the choice was dictated by how much space there was. Several cars of the period had the knock off within the fuel tank but in the end I could make a piston type that would fit in the very limited space. With such a close fitting body in mind, the fuel tank had to be tapered both in plan and side view and with rounded corners top and bottom on the outer side. Having been brought up in the days of tinplate work as a normal activity this was a bit fiddly but with a few basic dimensions fitted OK. Not a lot of room anywhere so the body had to be pretty tight fitting and having seen a Hungarian car with a body similar to what I envisaged the choice was either blue foam and GRP or carved Lime. With an inherent dislike of GRP it was the Lime and as most of my carving chisels have not seen a whetstone since retirement I resorted to my usual trick, machine it, so time for another short diversion methinks?

As a student in London I almost took up residence in the machine shop where we had every possible metalworking facility, but for our exhibitions we had to show the use of wood as well. Now some produced entire bedroom or dining room suites or similar, all exquisitely made to a standard I knew I could never match, but what I did have was engineering skills, so all my woodworking projects, large and small were produced using these techniques. The result, instead of hours of carving a block of lime it was on to the Emcomat and an hour with a ball nosed mill until the bottom half fitted the pan and all the internals. Next the speed cowl and a boring head produced the hole for the cylinder and a mill the basic streamlined shape. Already I can hear the howls from the traditionalists yet a bit of carving and sanding and there it was, ready for sealing and painting. Unusually, the pan was already painted so this was retained and for the top I went for Swiss red but it needed some identification so with a little trepidation I asked if I might use the original owner's SMCC number. Having gained permission for this I decided to add his name as a tribute to both him and a project that had been waiting to be completed for around fifty plus years.

The Saga continues: Hooray, at last, although having to be run under strict Covid regulations the first meeting at Buckminster and our maiden visit and what a wonderful facility it is. My initial enthusiasm was somewhat dented by the almost total destruction of my 1.5cc car that gave a very good impression of the cars from the silent movies that used to fall apart as they drove along. Front wheels were still OK, but that was about all, even to the extent that one side of the pan had split and opened up like an air brake. Whether it could be rebuilt at all would have to wait until it was on the bench so it was plan B and an aged Stelling 3B that had been retrieved from the shelf. Unfortunately, this displayed an irresistible urge to turn in to the circle every time it was pushed off, Aaron Monk telling us that it had no pull on the cable when he was trying to horse it. Balance seemed OK, but it was not until it was back on the bench that another tale of woe unfolded.

|

At some stage in its long life a new engine and front suspension had been fitted and in each case neither were aligned properly. The rear axle was angled something like 25mm out and the front about 12mm in so steering the car in a perfect circle off the track. Having removed the spur drive unit urgh, each hole for a 4mm screw was at least 6.5mm but the rub was that the unit could not be realigned as the exhaust would not clear the tether bracket. David Giles kindly suggested realigning the mount where it would fit and then drill pan and mount for dowels to keep it in place. This revealed why there were two plates on the underside of the pan, to disguise the huge holes that had to be slotted even further to get the motor in the right place. Now of course, the body would no longer fit so that had to be cut away further and a new, remote glow attachment fitted. Difficult to believe that an established competitor would build a car like this and then sell it on, or perhaps that is why they did? |

|

The summer was actually something approaching normality with regular visits to Buckminster, general maintenance and modifications on the Track Day Special along with the IP shunter described previously. Modifications to the 3B had worked so that was snaffled by ‘herself’, Martin Coe had found settings on my Redfin that had that running pretty well and the RYTM Ferrari 321T was performing faultlessly leaving more pondering time as to possible ways forward for better and faster cars to build for the following season.

|

I had built a retro cum modern style 10cc car to run at Gt Carlton but had been dissuaded on safety grounds so this was dug out and the decision made to scrap most of it and start again as this seemed a reasonable way forward, a modern style car with relatively low tuned and readily available motors using parts that could also be freely obtained. Just a question of sourcing parts, been there before so feelers out for possibilities. We thrive on coincidences and another of those odd and unexplainable occurred during the summer that had its origins at least four years previously. On a visit to the local Model Engineering Exhibition, a friend mentioned that he had an OPS 60 for sale on ebay but with no bids, would I mind bidding on it? An early Redhead and not worth a lot and in the end, that was what it was knocked down to me for. It was only when I went to pick it up that I realised that it was one of the much more rare Zimmerman versions that had been so successful in cars in the late 1960s. No immediate use for it so it sat on the shelf until an email from Germany. |

|

My mentor had visited Horst Denneler when travel was still possible within Europe and had asked him on my behalf if he had any 1960s parts still left and there the coincidences came thick and fast. He still had in his collection the car that he had raced in the late 60s with a Zimmerman OPS, but better still an original pan and set of gears, would I like it, oh yes. In addition there was a modern pan that would fit a 5cc motor on offer so things were looking up, assuming that the freedoms we were enjoying would eventually allow collection or delivery?

|

The September trip to Gt Carlton saw the demise of the ‘Goer’ aircar after thousands of laps of the track led to terminal metal fatigue, so time for a redesign and rebuild of that with a new chassis and front suspension, arise the ‘Phoenix’. Shortly after, a knock on the door late at night revealed a courier with a large box from Switzerland with the two pans as newly imposed requirements for quarantine precluded meeting up. Autumn projects sorted, just needed wheels, tyres, gearboxes and a serious amount of machining. The plan for the modern car was to use OPS 29s, which should be more than fast and tractable enough for Buckminster and for the as yet to be sourced 3.5cc version, CMBs. Lifting of restrictions here had at last allowed an Old Warden weekend where I found Katie Higgins with a crate of new OPS 29s that included pipes, which were available for less than the cost of a pipe on ebay so I ended up with enough to keep going for a few seasons at least. A new CMB 3.5 was also handed over for the second Buckminster car and orders placed for all the hardware needed before Brexit confused the supply chain. |

|

Unfortunately, the second wave of Covid saw the whole plan go to pot with the result that five months on, no parts and two stalled projects. All I was able to do was rough machine one pan, which required a large piece of aluminium as a jig and another bit of luck. On a visit to Eric Offen I espied a huge lump of aluminium plate in his garden that he was happy to part with, reckoning that it was part of the plating from an armoured car. I could quite believe this after having sawn it in half by hand.

|

|

|

| Denneler Pan and gear set | Finished chassis 50 years on | Fully clothed |

The Denneler 10cc car came on by leaps and bounds by comparison as I had a pair of rear wheels and four suitable tyres. The real head scratcher was the gearbox that was bolted to the bottom of the pan rather than on the same surface as the engine. Even more unusual was that the coupling between engine and gearbox was inside the flywheel and almost totally rigid with no margin for non alignment at all so that the bottom of the pan had to be machined out to exactly the thickness of the gearbox to the centre line of the axle and input shaft. Next to impossible to get it exactly right, but give it a go. The gearbox was fun as well as it stretched my two small machines and my hacksawing arm to the limit. First success was that the gearbox ran so smoothly that even I was amazed as it was all done by measurement and crossed fingers.

Having completed the gearbox and machined the pan there was no going back, engine and gearbox have to go in as one unit and then tighten up seven screws. Four months on I still can hardly believe that the gearbox and engine turned without any binding whatsoever, the worst element concluded, all relatively easy from there on in. Apart from the cut off that is, which was devious in the extreme and took me ten attempts at the spring and several redesigns before it worked. The size of wire was the key, 1.0mm was too soft to work, 1.5mm far too strong so a piece of the old 1.2mm, A Class cable had to be dug out. The front suspension is two swinging arms that the deconstructed 10cc car provided, which matched the original, with wheels machined from scratch. Tanks are no problem although there was not a lot of room as it is a very short pan and the pipe support was simplicity as many cars of that style used a plain bar extended from the back of the car with a support on the stinger.

|

|

| 5cc pan on its plate stretching the Emcomat to its limits | OPS nestling in the pan awaiting parts delivery (still) |

Ah, what about a body, well with nothing too much more on the horizon it was carved wood again, but this time Balsa as the body is huge so large piles of shavings and dust everywhere. Again odd, but several cars converted to tuned pipes had to have the pipe removed before the body could be put on or taken off so even more carving and sanding and then raiding the drawers for the tights and a session of doping. Another one waiting for the spring and warmer weather for painting as we were well into autumn by then and goodness, after the freedom of the summer and a final trip to a very wet Gt Carlton and a much drier Buckminster it was suddenly Tier 4, lockdown in all but name, and then full lockdown again. Sanity was maintained by a buy from the sale table at Buckminster where David Giles was offering a chassis and gear set for his Papagai 3B car. Oliver Monk had also obtained a supply of 2.1cc Junior cars parts from Lev Shprints but these were snaffled almost immediately before I got back from horsing duties so I succumbed to the Papagai with very little persuasion. Now, I have to admit that I had lusted after one of these for years as the engineering was superb but there was little chance of David parting with one of his spare sets, but time moves on.

With all the precision machining already done this was again relatively quick as the modern spares box provided a pair of wheels that had been slightly flatted during one of the regular CMB lock ups, but perfectly OK for Buckminster. The nerve wracking bit was that the Novarossi had to have the fins and head machined down to fit the chassis and the crankshaft clutch extension ground off leaving the small matter of a supply of 1/8th Whitworth screws to find, good old ebay. Pretty standard front suspension with a relatively soft damper and then just the fuel system. Now David had suggested that the tank needed to be moved outboard a bit and I was less than happy about drilling a hole in the side of the crankcase for the needle so a bit of lateral thinking and the kind offices of Norman Lara had a nifty Nova needle valve working as a wickfeed in a rather stylish venturi. Abandoned tinplate for a silver soldered, brass tank this time and there was another car, although still missing a few important parts through the reported closure of Novarossi, and a serious illness closer to home that has halted further progress. Even ebay has yet to come up with the goods, but we search in hope.

|

|

| Parts on the sale table at Buckminster | Just waiting for an exhaust (and a body) |

In a way this brought me back to where I started as desperation compelled me to dig out a project that has been on and off the bench for years without much progress. Amongst all the stuff that we were lucky enough to get a few years ago from the late Les Williamson was a large box of assorted. This was all the surplus bits from his career in national and international tethered car racing that did not belong to any of his cars. That there were still the rags, fuel, oil and nitro and other unmentionable liquids in the box meant that it stunk and the bottom level was solidified gunk of an unidentifiable nature. From this had came enough parts to build an Ian Moore style 5cc car some years ago and a selection of unrelated items, including a couple more 5cc body shells, one so badly mauled that it was a lost cause. The other had a large number of holes and odd cut outs but a plan was forming. Could I utilise what I had with other assorted bits from the box to make another car, so using up absolutely everything that was to hand. Another quirk of fate as a gash spur mount off ebay fitted a spare ETA 29 and with a set of gears from one of my Gt Carlton boxes the whole lot fitted into the body with all the holes matching up, unbelievable. The front end was a mass of holes but a new axle assembly and a couple of replica ZN wheels had it on its wheels.

|

|

|

| Two 5cc cars built from Les Williamson's 'spares parts box' | The 'C type' Auto Union | |

None of the wheels are particularly nice as the rears are 1950s vintage that had the screws drilled out many years ago with little thought to accuracy, while the fronts were as crooked as the proverbial donkey’s hind leg. First the bearing housing has to be machined round, central and at right angles to the hub. Of course that means the holes for the tube that hold a ZN wheel together now wobble like a goodun so that has to be bored as well before they were even remotely useable. The top of the body had a slot for the knock off arm but this dictated that the cut off had to have its bottom radiused to fit the pan and none of these exist, do they? Too strange to even begin to understand but from another source had come a sprung loaded knock off with the base already filed to a shape that fitted perfectly, even the fuel pipe was perfectly bent to meet the ETA needle, could not make up a coincidence like this. A quick session had the tank completed and apart from sourcing a period socket for the remote battery, the labours of the year were at an end, if for no other reason than there is almost nothing left on the list. Works out at one car a month without taking into account diversions and short term jobs, even I am shocked, but it’s all down to lockdown.

Then came Boris' press conference and the roadmap that made all the work on the FEMA cars pointless as we were no longer allowed to travel and within 24 hours the cancellation of the European championships put the kybosh on that trip as well. Even the domestic season could not get underway on schedule as it would be at least another twelve weeks before any sort of activities resumed. There was now plenty of time for one more project and an unusual starting point, as for once I have a finished body, the Auto Union that the late Keith Bragg started on but never got beyond the woodwork stage and collecting the parts for the chassis and running gear. He completed the bit I hate and I could do the rest as something of a tribute to Keith and his superb modelling skills. Along with the finished body and a box of bits came the original Drysdale plan with a detailed and hand drawn plan of the body, this was going to be easy, probably less than a week from start to finish? Then it would be back to pondering and waiting for inspiration, parts, another lucky find on ebay or something exciting lurking, forgotten in someone’s workshop.

Like most plans at present, that time scale was shot to pieces when spreading out all the relevant parts on the bench revealed a major flaw. The Drysdale plan is for an Auto Union D type with what is essentially a 1066 type chassis and running gear and a carved spruce and balsa sitting on top of it. The drawing Keith had done was for a D type, yet the body he had made so superbly was a rib and plank C type, built boat hull style on a ply former. If the Drysdale chassis is used then the whole of the bottom of the body has to be cut away and two long slots cut into the either side for the axles but there is no way this could be done with the method of construction used as the body would literally fall to pieces. The only clue as to what Keith had in mind was a subframe under the body made from two pieces of aluminium railway track that gave the whole thing some rigidity.

This called for a plan B, which did not exist so cue much head scratching and thinking until a way forward began to emerge. Everything would have to be attached to this subframe somehow and all the chassis components ditched apart from the gearbox and wheels. The axle line for this car is almost halfway up the body so the front end would have to be slotted for the gearbox, which meant lots of reinforcing and anxious moments cutting through the building frame. The rear axle is above the suspension fairing so could not be slotted up from the base, so this has to pass through the body shell as on the full sized car.

The suspension as specified could not be used either so all that had to be redesigned to work from a series of flat plates across the subframe with uprights outside the body in what little space remained and it is tight at both ends. Tether brackets and the engine mounting plate all have to be attached to the web of the 5" gauge rail with no room above for nuts, so every hole is tapped 6BA and then a bagful of very short screws converted to countersunk to hold it all together. With the axle and engine plates right across the subframe, that is now rigid enough but I am not sure about holding the body down with just four self tappers into 1/8th ply. As Christoph pointed out, will it be strong enough to go round and round in circles, probably not without the body disassembling itself?

As soon as one design problem was resolved, another would emerge that required a new line of thinking and the next was the engine and drive line. The plan and hardwood body allows for a tall 5/6cc motor, but even that has to be sloped downwards to get it to fit within the confines of the rear of the car. As the C type body was in essence an upside down boat hull, even marked port and starboard, there was a very deep keel running the length of the car that restricted the internal height considerably. Amongst the parts was an ED Racer that has been converted to reed valve and whilst hardly appropriate was still going to be a tight fit if the flywheel was not to drag on the ground, so Racer it was. Flywheel and clutch drum had to be modified as both had been drilled out, which meant making pressed in centres, turning a taper to match the crank on the ED and then a new crank nut for the clutch to run on as well as the new bush in the drum as that had been machined away entirely.

|

A week's job was now headed towards a month before the chassis was complete and the body could be fitted. Then the stark realisation that the lid on the engine compartment still would not fit because of the compression screw. A bit more machining on the engine mounts and an Oliver style compression screw had it looking like a complete car. For once, and having a bit (lot) of spare time, I decided to add some scale detailing, a dashboard, steering wheel and flyscreen, but baulked at the sixteen upswept exhaust stacks, unless I get really bored at some stage. A traditional wire bridle finishes the project off, and whilst I could have done some things very differently, it would have been at the cost of Keith's superbly built body, which would have largely negated the original plan. |

|

Well, a month on from the landmark of one year of Covid restrictions and as it seems likely that we might be able to get back to Buckminster and Gt Carlton shortly, it is time to sort out some cars to run, which is roughly where I was eighteen months ago at the start of this saga.

©copyrightOTW2021