|

Home Updates Hydros Cars Engines Contacts Links ←Previous Contact On The Wire |

|

|

John Goodall Building and racing retro tethered cars |

M&E Wasp rebuild

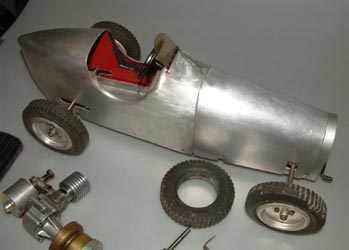

A few years ago I obtained an almost complete M&E Wasp tether car missing just the front drive wheel discs and hub and off a very good friend, the body parts for another car. Strangely the tyre and fixing screws were with the car? I decided to try and help an enthusiast in USA who was advertising for a Wasp through the excellent and free OTW advertising service. He seemed very keen on my offer to let him have the almost complete car provided I found the missing wheel discs and hub. I did not expect to find the correct wheels discs in useable condition having searched for some previously for the car. The hub is a simple turning operation on the lathe, but the wheel discs entailed making a suitable press tool to produce the discs in exactly the same manner as the originals, so that they matched.

One of my first jobs after a five year engineering apprenticeship was as a "Jig and Tool " designer, so this came fairly easily to me. The only difficulty was in getting the correct pinch on the tyre by adjusting the hub width, once the size was determined; it was very easy to replicate the hubs for the other wheels. A simple drill jig was used for drilling the hubs and the wheel discs, so they line up well using the bore for location. The drive wheel hub only is fixed to its shaft with, in my case, a socket head 6BA grub screw, this is neater and a better solution than the original bent L shape idea? The bent end may or may not be in the correct place to fit between the discs and if not, what happens?

|

|

|

| Starting point |

Original painted grill and starting handle. |

Original windscreen and steering wheel. |

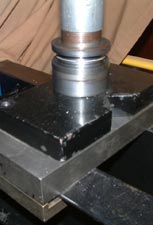

I made a punch and die in mild steel, which I deemed adequate without hardening for the fairly small numbers needed. When making a punch and die combination, the die usually forms the outer dimensions and the punch the inner with the clearance between them governed by the material thickness plus a small clearance tolerance so that binding does not occur and it is also easy to remove the part from the tooling. An essential feature of any tool design is some form of location so that the material blank sits centrally within the tool. I decided to use the central hole in the wheel disc which also keeps it central on the hub assembly and to use this location in all the ensuing operations, so the appropriate size hole was drilled into the blank alloy sheet after marking out the blank size required with a calliper.

It is always best to check the press tool result on the first example to see if it is the correct size and form after pressing, as it might need adjustment. The disc blanks were then cut out using hand shears as accurately as possible. The discs were pressed up using a hydraulic press I have for basic garage work on my vintage motorcycle repairs. Adjustment in clearances and corner radii is sometimes needed after the first two or three pressings and when satisfied I made up two complete sets plus the spare pair needed for the car to be sold to USA. The outer diameters were trimmed afterwards using the press tool punch as the fixture to ensure true running and with a pressure pad to hold it onto the punch using the tailstock. A form tool was then ground up and the excess material on all the discs trimmed off and deburred.

|

|

|

|

| Hydraulic Press | Press tool | Jig Drilling discs | One down seven to go |

I needed a clutch, gearbox, dummy steering wheel, dummy radiator grill, dummy seat, tether arms and all the running gear for the second car which I set about making before I parted with the now complete car so I had a reference to all of the parts that would be needed. I made drawings for wheels, hubs, the clutch and gearbox before starting on the chassis.

|

|

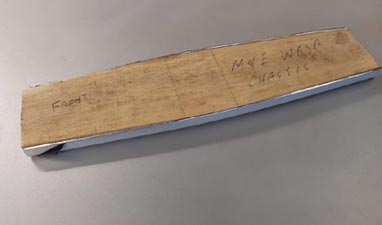

I made a plywood buck to manufacture the chassis pan in aluminium as one of the first operations in the new build. I used a wooden block to assist in folding the edges over to avoid excessive hammer marks often made without one. It saves a lot of work later in cleaning up and maybe prevents weakening the sides as well when these marks are filed up to remove them??

|

I had asked a few likely contacts if they might have a spare clutch and one thought he might have two and that one might be spare. I eventually obtained this, but did not see initially, in the hub-bub of a swap-meeting, that it had been badly modified before parting with a new original Dooling 61 crank shaft and connecting rod in part exchange and was also generously given £10 cash?? The clutch had also been modified to suit a smaller engine than for the intended and the more usually fitted ED 2cc Penny Slot. I had chosen this ED as it did not need an unsightly cut out in the bonnet (or hood?) for a compression screw. The main housing had been shortened, reduced in diameter and its bore had also been over drilled and I ended up only being able to use the clutch drive hub and the three clutch shoes, the rest had to be re-made to the correct style and size, turning the parts on the lathe. A much more costly operation in the end than envisaged. Right: ED 'Penny Slot'. The wooden mounting blocks are correct |

|

|

|

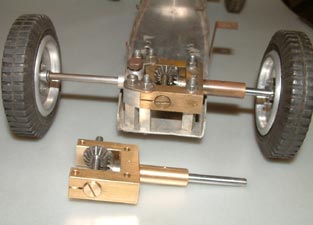

I had not found a gearbox for the second car so decided one had to be made and Hugh Blowers kindly found me a set of suitable 1066 bevel gears of the correct ratio to make the gearbox. I obtained some ½" x 1 ½" x 3 ½" long brass bar, marked it out and roughly cutaway most of the excess on the band saw. The final dimensions were machined on my Bridgeport milling machine with the output wheel bearing and its bore machined using a four-jaw chuck in the centre lathe. The input bearing and all fixings were drilled and bored on the Bridgeport using the DRO indexing and the gear centres came out almost spot on, just needing a four thou shim behind the drive pinion to obtain the correct backlash, just perceptible without tight spots. Bright mild steel was used for the two shafts with the gears pinned to them. Left: Replica steerable rear axle with original behind |

The final drive gear can only be fitted after the input gear is mounted on its shaft and an adjustable screwed end bush bearing fitted to remove end float. This is gripped solid when the gearbox is tightened down onto the chassis with a saw cut machined to clamp the bush and prevent movement.

|

|

|

| Original M&E Clutch with the much modified one from the 'trade' | New gearbox looks superb | |

Next came a dummy radiator grill made mostly out of brass sheet with the rounded top surround made in two pieces with a lower joining piece between folded to suit and the whole silver soldered together with high temp silver solder. This allowed silver soldering the wire mesh with a low temperature solder without melting the main body joints.

|

|

In hindsight maybe stainless steel mesh should have been avoided for ease of nickel-plating, but it can be achieved with a special process. It may have been easier with brass mesh although much softer. I made the side cheeks with two mounting holes each side to prevent the back and forth movement seen with just the single screw each side. I added a brass bearing for the dummy starting handle silver soldered into the cross member. This kept the spring friction device clear of the mesh for a better solution to the original. The starting handle was bent up from mild steel and a 6BA screw thread, with nut added to retain the spring. A dummy steering wheel was made up from brass sheet for the four support arms in the form of a cross. A central pivot and column was turned up in my small lathe in two parts and a ring for outer rim bent up in brass wire, the whole being silver soldered. Not perfect, but just adequate. The starting handle and steering wheel were etch primed and painted black. |

|

At this stage I drilled the fixing holes for the rear body to fit the chassis and made the cut outs to clear the rear axle. The slots were marked out onto masking tape, which also served to guide the drill and stop it slipping. For a hole to produce the radiused slot end; I usually start with a small pilot hole and open out to the final size. The slot was then cut with shears leaving sufficient material to file away any distortion. The bonnet cut outs were done in the same manner and I was pleased with the result. I decided to use a ladies wrist-watch strap to retain the bonnet, as they do look quite scale like. Right: Newly replicated parts and original body parts as obtained. Original clutch at right with the altered exchange item. |

|

|

|

The original Wasp had part of the dummy seat with the squab missing so this and a complete set were needed for the rebuild. Balsa 3/16" sheet had been used for the seat back, so this was replicated with grooves cut to simulate cushion pleats and the whole covered in self-adhesive black vinyl sheet folded over the edges. The seat parts were glued in place within the cockpit opening in the body rear end using JB Weld a two part adhesive that remains flexible and is fairly tough. I bought this for sticking carbon fibre on which it also worked well. I am now just awaiting return of the dummy radiator after nickel plating and the car can then be finally assembled. Left: Dunlop replica tyres on solid hubs and some close replicas plus dummy radiator and seat parts. |

Final assembly of the M&E Wasp, resurrected from a box of

assorted bits.

|

|

John Goodall Models the 1957 Vanwall

On a Thursday afternoon in late 1957 I passed my motorcycle Driving Test, just two days prior to the British GP taking place at the Aintree Circuit near Liverpool. I was serving an apprenticeship in mechanical engineering at FNF in Burton upon Trent and asked a fellow apprentice friend Peter Sherratt if he fancied a ride on the back of my few weeks old Triumph Tiger Cub to go to Aintree for the GP, he jumped at it being even keener than I was.

We travelled up in fairly good weather, parked the bike and found a spot to view the race in a U shaped part of the track between Cottage and Country corners. The entry list had all the top names entered from the great Juan Manuel Fangio, Peter Collins, Mike Hawthorn and lots of British drivers including Stirling Moss, Tony Brooks and Stuart Lewis Evans all three in the new Vanwall, with Moss being quickest in practice. In the race Moss was doing very well until the 51st lap when he pulled into the pits with a problem and the team called in Tony Brooks and Moss took over his car, now well down the field. Moss drove superbly well overtaking all other drivers to win after 90 laps of the 3 mile circuit, with Luigi Musso second and Mike Hawthorn third. This was the first British car and driver combination since Henry Seagrave driving a Sunbeam in 1927 to win a British GP in a British car. That is why the Vanwall still means so much to me.

Ian Harper took over The Oliver model car body patterns from Paul Ironmonger at the SAM 35 Octoberfest in 2004 and later asked me to join in his venture and I said I would help in any way I could, which I was very happy to do. I had always felt the Oliver car range lacked British content and balance with three Italian cars and only one British car, so I suggested to Ian we should add the 1957 Vanwall to the range and Ian agreed. So I made pine patterns and had the first batch of castings produced in Ian’s local foundry.

|

|

| Pine patterns ready for the foundry | |

The Vanwall castings after this initial batch of eight, will join all the other bodies available from Ian from now on and align with their prices. My first Vanwall won the inaugural Redfin Trophy event, but built on the Redfin chassis with a wooden body was eyeball scale only. The new Oliver version is much more accurate in every aspect and available from me on Market Place.

.jpg) |

.jpg) |

| Castings fettled and joined | |

I commenced building the new prototype and matched and joined the two body half’s secured with M4 CSK socket head screws as the first step and then cleaning up by hand filing the casting exterior and joint line before final polishing with abrasive tape to my satisfaction. I intended adding both front and rear suspension to cope with the Buckminster track condition, so I next concentrated on the motor platform for a new Redfin Twin Shaft engine I had in stock and its brass hinge at the forward part of the mount. This 1/8" Dural mount is controlled by a spring damper unit filled with oil and found on Ebay. The copious space inside the Vanwall body makes this an easier task to fit in than on either of the stable mate Ferrari, or particularly the Mercedes cars I had previously built with the rear suspension idea pioneered by Ian Wingfield. The control arm is taller and gives better leverage restraint allowed by this extra space. The travel is limited at front and rear by drilling into the body axle cut outs above both axles and inserting a plug of "O" ring rubber to arrest movement, this works well too and stops metal to metal noise at full deflection. The mount was extended at the rear end to support a Mike Francies 3D printed 'curly carb', which fits neatly inside the body, drawing clean air without unsightly body cut outs which I hate on a scale car.

.jpg) |

.jpg) |

| How all the 'works' fit inside with just the cut off protruding | |

The front suspension utilised a milled alloy trailing swinging arm pivoted at its forward end, and this time controlled by anti vibration rubber spring damper units which are self damping, made for Quad copters/drones Ian suggested using them and I have to say they work very well. The smallest can be pushed inside the larger ones to stiffen up if needed which is what I did with a small unit placed below the arm to control the rebound. The axles on both front and rear suspension pivots are made from 1/8" diameter SS and held in place with grub screws to prevent sideways movement on the move.

.jpg) |

.jpg) |

.jpg) |

| Brass trunnion blocks | 3D printed 'curly carb' | Internal layout of suspension |

In practise the car is very stable on the track where it ran for the first time at the SAM35 Redfin Trophy event on 14th June 2025. The body is a little on the heavy side, but this seems to help the stability. Standard Redfin wheels and tyres are used front and rear. I did find it necessary to mill out below the engine mount rear end to give maximum ground clearance.

|

|

| On its wheels and ready for detail finishing | |

I made the four branch exhaust from solid 3/16" diameter copper rod bending as shown and then joining with hand filed contoured tapers and flutes to give a good fit for silver soldering at the tailpipe junction. If you are adept enough you could use a round end 3/16" diameter end mill to rout these. One of the centre pair of pipes is left longer and a recess turned on it to locate the brass tailpipe, this obviously has to be done before bending. Forward Planning! Is sometimes essential! A 3/16" OD brass tube was cut and bent to follow the body curve fairly closely as on the full size. Two securing exhaust pipe brackets were made from brass close fitting turned narrow rings with 8BA brass screws silver soldered to them. These were fixed to the body through two holes drilled and counter bored inside to accept 8BA nuts. The lower end of the four branch exhaust had a 1/32" thick brass plate silver soldered to join the four ends and to provide a stop inside the body, where a cut out was drilled and filed for the tapered end to pass closely through. This serves to hold the exhaust forward end with no movement with the four branch resting on top of a sloping ramp filed from the slot rewards. The whole exhaust was nickel plated after a trial assembly.

.jpg) |

.jpg) |

| Superbly modelled four branch manifold before plating | |

The fuel tank was made from brass sheet and copper pipe for feed and forward facing vent. A screwed filler was made and soldered into a hole cut in the nose of the tank. Three brass mounting brackets are soldered on and used to raise the tank to align with the jet centre. One of my last Redfin cut offs was modified using the obligatory larger brass latch cone and next higher wire gauge to prevent premature self tripping.

The tether arm was made from SS and attached to the cast in boss in the bottom half or chassis in the usual Oliver fashion with two socket head screws. I added a dummy radiator grill set back inside the nose to hide the front suspension and trapped under it.

.jpg) |

-(1).jpg) |

| Arrangement of Csk screws in pan | Prototype and finished model as run at Retrofest |

The windscreen like the four branch exhaust was intended to be available from me using 3D printing along with the body castings to help the builder, but so far the commercial attempts over six months have not proved satisfactory, so I found some clear soft and flexible plastic sheet 1mm thick on Ebay and cut this using scissors to suit the cockpit edge shape and glued in place after painting using ultra violet curing clear glue named "Quick Fix", which cures in about three seconds only. It is best to apply this to the joint area and hold the top of the screen in a U shape to match the cockpit outline with upper edges naturally sloping inwards to align with the back rest upwards taper with drafting tape which peels off easily later, sit the screen down with the rear ends aligning with the cockpit profile and tape to hold if needed and cure with the UV device supplied all less than £10 with most of it still left. I had the body stove enamelled in British Racing Green and this glue holds the screen rigidly well on these stove enamelled surfaces with no damage at all, even after using the stop brush. I believe the flexible plastic helps in preventing damage as a bonus. The first car windscreen I made five years ago from polycarbonate did not survive the brush cut out stop, but that was epoxy glued on to acrylic spray can paint.

|

|

| The finished car looks superb, especially running on the track | |

I found a company on Ebay who made me two sets of "Vanwall" white Vinyl self adhesive stickers 40mm long O/A and 10mm high for less than £12, so less than £6 per car, the company was fab_beauty_accessories, and they did a fast turn round as well. This completed the car with some white vinyl racing numbers added, again available cheaply on Ebay.

©copyrightJohnGoodall/OTW2025