|

Home Updates Hydros Cars Engines Contacts Links Contact On The Wire |

More Tales from the 'Garret Workshop'

The original Lockdown Saga, and my earlier 'Lament from the workshop', were brought about by Covid and having nothing else to do for many months except stand at the workbench and make things. That was, of course, five years ago now, so it may be of interest to know what happened to the projects featured, what has followed, and several asides along the way. I always enjoyed reading the Dope and Castor columns in Model Cars and later Model Maker as these were full of asides and tit bits of information. Those of us 'of an age' will know that the 'Dope' refers to any fuel used other than petrol and of course the Castor we still use, except in those days it was probably Castrol R, oh the smell hanging in the air? So the 'Tales' are very much following the lines of D&C. I do not do high quality and precision engineering like Oliver Monk, so do not offer advice on processes, neither do I do fiddly and exquisite model making like John Goodall and Steve Betney, I just build things, and lots (too many) of them.

A bit of context might help though. Workshop is a rather grand term for a small bench in what 150 years ago was a tiny, 3rd floor servant's room. Machinery extends to a Unimat lathe and Emco bench mill, so all projects are constrained by the facilities and space. Importantly though, having come from a sport where my life and that of others was dependent on nothing breaking, coming apart or falling off this has determined the style of all my subsequent work.

Apart from the very first car I ever built, a Rowell Rapier, all my subsequent builds and restorations have been based on existing parts that have come to light, reconstructions and other builder's 'roundtuits' (a lot of them). Unlike a very dear friend who is a prodigious builder yet never parts with anything, and subsequently has a house full, and I do mean full, much of what I have built gets sold on in order to fund new projects or trade up and avoid total storage chaos. The only ones that stay the distance are those with a bit of history, connection, rare or of use. Working as I do, sourcing parts can take ages. For older cars it is a case of asking around, advertising, scouring swapmeets or hoping that something turns up. This inevitably means that there can be any number of projects running parallel, some stalled waiting for parts and others moving on as bits are found. The final project featured during the lockdown lament was the beginnings of a 5cc FEMA style car for use at Buckminster and illustrates just how long a build can take when parts are not freely available as it was not completed for another four years, and it was not from want of trying?

|

|

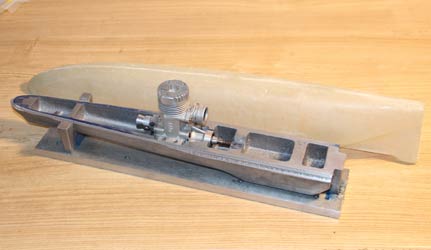

| A lot of pan on a small mill | The starting point, pan, body, gash motor |

This car had its origins several years previously when Kate Higgins was selling her late father's collection of engines at Old Warden. Amongst these were a number of NIB OPS 29s, with pipes, ideal, as OPS 5cc cars are still being run fifty plus years after the engine first appeared. A while later came the offer of a new pan and body from Switzerland that came via post as we missed two whole seasons of travel through CV. However, a series of events just prior to and in the post CV period have seriously affected both myself and many other builders, compromising almost every project that has crossed my bench since. The two individuals moulding retro tyres in Hungary and modern tyres in Germany both retired, as did the engineers responsible for so much of the material coming out of Germany. The embargo on Russian goods after the start of the Ukraine conflict took out several other valuable suppliers. Parts and engines from the Ukraine became severely limited, extending the time scale of builds to years, rather than weeks or months.

|

|

| Huge amounts of swarf later | Everything in place, still on mounting plate |

In the case of the 5cc car it was two years before I could get hold of the gearbox and wheels and only then because we were at Kapfenhardt and I could pick one up from Denneler. Even so it was yet another year before I could source the coupling, and that came from a Polish competitor. So, with gearbox, a coupling temporarily robbed from another car, motors and pipe, construction could get underway, always making allowances along the way for the small nature of my machines. All pretty straightforward until the inevitable mmm, moment manifested itself. As has been related before and will be repeated regularly in these tales, working with parts sourced from here, there and everywhere always results in something not quite fitting or there being no room. Usually there is a way out with a lot of pondering and some lateral thinking, and that alone can take ages, apart that is from one disastrous case related some while ago, where no amount of ingenuity could retrieve the situation. This time it was that there was no room for the venturi and needle valve, sorted thanks to David Giles having made an alternative backplate 45 years earlier.

|

|

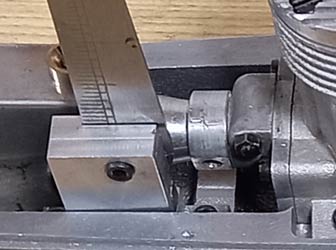

| The venturi problem | The solution |

With CV and the further attendant delays it was 2024 before the car was finished and painted, ready for its Buckminster debut in 2025. initially proving a pig to start until it suddenly fired up and a needle setting could be established. Straight on to the track, pushed off by herself, horsed up by me and joy of joys as it came up to speed without any problems, followed by dismay as it slowed to a halt a few laps later. A gentle turn of the wheels indicated that all was not well in the engine department and a strip down revealed another failure of the OPS' Achilles heel, the big end, where half the bush had dropped out, luckily staying in the crankcase. Eventually I was offered the correct replacement, but that would have had to wait until the 2026 season, but by chance, amongst all the material for sale at Buckminster swapmeet was a box of OPS 29 spares with a new rod, so it is all back together but facing a seven month hiatus before knowing if all is well again.

|

|

| Mounting feet machined off, now on its wheels | Body fitted, awaiting warmer weather for painting |

|

|

| Project finished | OPS motor finished? |

There is some good news though in that limited ranges of tyres are now being made in Hungary, Poland and Switzerland, some parts are available again from Italy, Poland, Hungary and even Russia but it very much depends on personal contact and being on hand to pick them up.

ęcopyrightOTW2026