|

Home Updates Hydros Cars Engines Contacts Links Contact On The Wire |

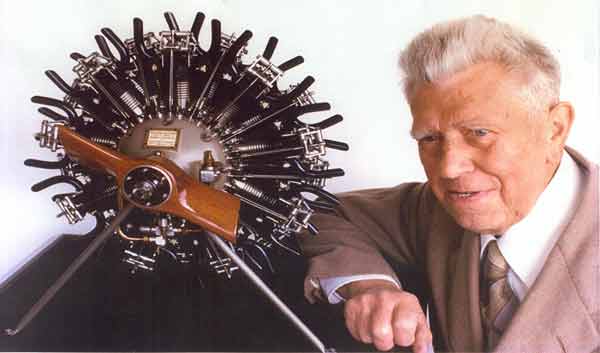

Gerald Smith. " My Life’s Work and Hobby".

Photograph supplied by the late John Scott-Scott

Whenever a Gerald Smith engine comes on to the market you can be sure that it will create a great deal of interest. The sale of Gerald’s own collection confirmed that these motors are amongst the most desirable in the eyes of the collectors. Each of his engines was an engineering work of art and in a completely different league compared with other engines available at the time.

Who was the person who produced these, the ‘Rolls Royce’ of model engines? Sadly, Gerald died in 1990 aged 88, but thanks to the late John Scott-Scott the following transcript of two lectures Gerald made to members of the Rolls Royce Heritage Trust in October 1987 give a good insight into the man, his career and his involvement in model engine production. John Scott-Scott not only knew Gerald but had also been largely responsible for the engine collection over the last few years. He was the leading authority on matters relating to Gerald Smith.

Aviation.

Gerald joined Siddeley-Deasy (later to become Armstrong Siddeley) at Easter 1919 as an indentured apprentice, working on Puma engines and tooling for the Siddeley-6 car. Two years later he entered the airframe section of the company working in the fitting shop, assisting in the building of the ‘AWANA’, a twin-engined troop carrier aeroplane with a tubular steel fuselage. Whilst in this shop he was ‘noticed’ by Mr Lloyd, the chief designer, who arranged for him to move to the Aero Drawing Office. Soon after this Armstrong Whitworth Aircraft was formed in the Burlington Building and Gerald embarked on three years of general design work on various aeroplanes. These encompassed the SISKIN, ATLAS and ARGOSY 1 for Imperial Airways, the latter having three Armstrong-Siddeley engines. Gerald also investigated the installation of a ‘Panther’ in a ‘STARLING’ aircraft, which was based on the SISKIN and numbered AW 14, the first Armstrong Whitworth aircraft to have an official number.

By this time the Aero Drawing Office had grown to 40 members and Gerald worked directly for the Chief Designer. In 1928, more ‘ARGOSY’ orders were received and Gerald was called on to design a long-range fuel tank. Having a semi-streamlined shape it was very difficult to calculate the capacity? 180 gallons were stipulated and Gerald was much relieved to find that the final assembly held 183 gallons! He then worked on the ‘Jaguar’ engined ‘ARIES’, of which only one was made, passing on to designing the interplane struts for the ‘ATLAS’. Gerald said, " This task was the most difficult piece of geometry he had ever had to solve".

In 1930 the Drawing Office moved from Parkside to Whitley and Gerald was put in charge of the landing gear section. This led to him designing undercarriage parts for the AW 15 ‘ATLANTA’ which had a 14ft wheel track, with the oleo and radius arms enclosed within the fuselage, a very advanced concept for that period. Eight of these aircraft were ordered by Imperial Airways, each being fitted with ‘Double-Mongoose’ engines.

In 1934, there followed work on the AW19, a torpedo-carrying biplane with a ‘Tiger VI’ engine. Only one was made, which after trials became a test bed for the ‘Tiger’ engine that would be used in the early Whitley like bomber, the AW23. Gerald was involved with various aspects of the undercarriage for this type of aircraft. He recalled one in particular, where he elected to operate from his own workshop, in his own time as a sub-contractor The work was to design and supply landing gear switch assemblies for the ‘WHITLEY’ bomber, a contract which finally ran to 1200 units! The Drawing Office staff kept increasing with the perceived demands of the approaching war and at least two complete aircraft designs were being progressed at any one time. An example of this was the AW29, intended as a fast day-bomber, which was being drawn up side-by-side with the developing Whitley family. The AW29 had a ‘Tiger’ 8 engine, but the prototype underwent a wheels up landing and was used as a test bed for the ‘Deerhound’ engines for a few flights before testing was transferred to a Whitley.

Next came what was possibly the biggest challenge to Gerald’s design expertise, namely the AW27 ‘ENSIGN’, which was by the standards of the day, an enormous aircraft. It had a wingspan of 123ft and 14 of these were made with, fitted with Tiger 9 engines. Gerald produced an innovative solution for the undercarriage of this aircraft, which had wheels 6ft in diameter and a very tall retraction system, being a high wing monoplane. His design solution earned him a patent award, and to show his faith in it he participated in the air tests and demonstrated the feasibility of manually lowering the undercarriage when required for emergency reasons. Not many designers actually submit to such a real-life test of their beliefs! By now Gerald was in charge of both engine installations and fuel systems as well as his existing responsibilities on undercarriages.

1938 saw the first flight of the Merlin engined version of the AW38 Whitley, the design of which had obliged Gerald to make regular visits to Roll-Royce at Hucknall on various aspects of engine installation. The next aircraft design was the AW41 ‘ALBERMALE’, a concept using only wood and steel, in view of aluminium becoming a strategic material. The aircraft was fitted with Bristol ‘Hercules’ engines and made its first flight from Hamble in March 1940. Before its eventual production, significant changes to the wing size were necessary as that first flight nearly ended in disaster, but that was another story, which Gerald knew well, as he was watching at the time.

With the increasing air raids on Coventry, the Armstrong Whitworth Drawing Office at Whitley was dispersed to the Golf Club at Milverton, where it stayed until 1945. Much of its work was on modifications to existing designs, such as the ‘special Whitley’ for the Milan raid. Work also proceeded on laminar-flow wings and the AW52 glider project. Extensive internal modifications to a ‘Sky Master’ were also completed in this period, adapting it as a ‘flying caravan’ for Winston Churchill, having chairs, tables, a bedroom, water systems, extra fuel tanks and a generating set. In 1946 Gerald Smith resigned from Armstrong Whitworth to set up his own engineering business in Nuneaton having spent 27 very interesting years within the Siddeley organisation.

Engine Builder.

|

Whilst still at school, Gerald had developed a lasting interest in internal combustion engines and soon after joining Siddeley-Deasy he purchased a 5" Drummond lathe. On this he proceeded to make his early engines. In 1922, the first of these, a 22cc air cooled four-stroke, won for him the first of many awards at the London Model Engineers Exhibition. The next, a five cylinder four-stroke radial also gained an award two years later. This encouraged him to set out on the design and construction of his most famous pre-war engine, the eighteen-cylinder, twin row radial. This began in 1924 and took six years to complete. The resulting masterpiece won for him the Model Engineer Championship Cup and silver medal at the 1930 ME Exhibition. The engine was subsequently exhibited at the Armstrong Siddely offices in New Bond Street, London, where it was photographed alongside one of the Company’s radial engines. Gerald’s engine, however, had eighteen cylinders with four valves per head as opposed to the A-S then in production that had just 14 cylinders Articles detailing the construction of this complex engine can be found in 'Model Engineer' July 14th 1927 and September 25th 1930. |

In 1936 he built himself a new workshop and then proceeded to design and build three 15cc single cylinder two-stroke model aero engines. His time was primarily occupied with the ‘contract’ manufacture of the large batch of undercarriage switches for the Whitley bomber. The new workshop was badly damaged in an air raid on Nuneaton in 1941, so there was an enforced gap in activities until 1944 when he designed a series of engines based on the concepts proven on the pre-war 15cc engines. This led him to start his own small engine business after leaving Armstrong Whitworth in 1946.

In all he made over 300 engines (see part 3 for engine details), known to this day by engine enthusiast and collectors all over the world. The names Magpie, Lapwing and Redwing are secure in the annals of small engine history. Unfortunately, this production line was brought to an end in 1949, due to the introduction onto the model market of engines of a simpler principle (and hence lighter). These were the first American ‘glow-plug’ engines, followed quickly by British equivalents, and although many firms stayed on with their compression-ignition (diesel) engines the end for spark-ignition had come. The home workshop turned to producing prototype precision equipment for local companies, including Dunlop Aviation.

Photography became Gerald’s hobby for the next few years, until in 1979 he became involved with small petrol engines again. He was persuaded to design and construct a special 10cc spark-ignition engine for use in ‘vintage aircraft’. This was called the Skylark, fourteen of which were built completely by Gerald, even producing his own castings with his home facilities.

The success of these engines led him to return to four-stroke radial engines, in keeping with his pre-war achievements. Thus was produced the 3 cylinder Osprey followed by the 5 cylinder Buzzard. The sound and handling of these engines was unique as all of these latter engines had magneto ignition of Gerald’s own design. Starting was brisk, following a short prime.

|

Post script. In the remaining years of his life, following the lecture to the RR Heritage Trust, he organised an exceptional display of his engines at the Stoneleigh Model Engineering Exhibition, which became a national attraction. Sadly, by then he was beginning to feel weary after these efforts and his last few years were more restful, apart from machining the majority of parts for a 7 cylinder radial engine to be called the Kite. Unfortunately this project was not completed. He leaves us with an exemplary story and his engine designs have set all-time standards for both innovation and excellence of manufacture. The Kite was eventually completed by John Scott-Scott and forms an update to this article. Right:- Display of Gerald's engines at TEE two weeks before being broken up in 2005 |

|

The Engines

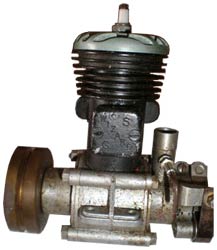

All of Gerald’s production engines, with one notable exception had the names of birds. The first of these was the type 7, 15cc Magpie, available upright or inverted for aero use and in two guises for marine use, one of which featured ducted fan cooling. Approximately 35 magpies were produced between 1946 and 1949. Engine type 8 proved to be the most popular and some 160 versions of the 10cc Lapwing were manufactured. Owing to the symmetrical design of the crankcase this engine could be assembled in a variety of ways to suit virtually every desired form of installation. It was even available without mounting lugs to enable it to be mounted horizontally on an aluminium bracket for use in tethered cars. It was in this form that Ian Moore put the engine to such good use in his MG record breaker replica. A Lapwing also powered Carl Wainwright’s ERA, and although horizontally mounted, used the conventional lugs and a cast engine mount. A smaller version of the Lapwing was the type 9, 7.5cc Redwing, which was similar in just about every respect excepting the cylinder dimension. The slightly odd capacity limited sales to around 85 units.

|

|

|

|

| Magpie | Lapwing | Redwing | Wizard |

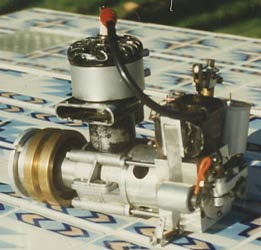

The exception to the ‘bird names’ was type10, the 10cc Wizard. This was based on the Lapwing with altered cylinder finning and cylinder head. It was intended for ‘full-bore’ race running in tethered cars so the complex ignition and carburation systems were abandoned for a simple needle valve and fixed points ignition. 30 examples of the Wizard were produced in this form with just one experimental aero version.

|

|

|

|

| Osprey | Buzzard | Aero Skylark | Marine Skylark |

Collection photographs by kind permission of Gildings

It is only through close contact with one of Gerald’s engines that the sheer quality of workmanship and complexity of design can be appreciated. Gerald manufactured all the parts for his engines, including the gear cutting, but then stove enamelled the crankcases, anodised the machined parts and engraved the crescent nameplates which each engine featured.

|

|

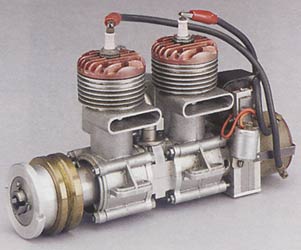

A Gerald Smith engine is more than just a model engine; it represents a pinnacle of aesthetic and engineering design, and owning one of Gerald’s engines one can appreciate the level to which he was prepared to go in producing these ‘masterpieces’. Detailed descriptions of many of the construction techniques Gerald used were written up by him as a series of articles in Engineering in Miniature and therefore can be researched by those interested in this aspect of his life At some stage it would seem that Gerald had a number of Wizard/Lapwing engines and parts, which he was unable to sell, and these were passed on to Vernon Gray, an engine builder and model shop proprietor from Leamington. These were fitted with magnetos, slide carburettors, and ratchet start flywheels for use either in cars, or in water-cooled form in large, radio controlled, model boats. Two of these motors were even coupled together to make a 20cc air-cooled twin. |

|

This was not to be the only occasion when Gerald passed on his castings, as an article in Model Engineer from May 52 shows 2 Lapwing/Wizards being constructed by pupils from the King Edward VI School in Nuneaton. The school had a model-engineering club, which met after school, and Gerald not only gave them the castings but original jigs and fixtures to aid in the construction of the engines. He was also giving help and advice to the school during this venture. Although Gerald advertised in the national magazines and displayed his engines at meetings around the country the quality of what he was producing meant that he was not always able to keep up with demand. In his trade review for Model Cars in December 1946 ‘Simple Simon’ reported, when reviewing the new Redwing engine, that. "I should warn those whose impulse is to throw away their worn-out motors with a view to immediate replacement with one of these desirable pieces of property, that it isn’t just as easy as that, deliveries being distinctly on the tight side as yet." In order to inspect the motor in ‘peace and quietude’ viewing of the engine took place ‘in the seclusion of the car park’. He further comments about the excellent workmanship and positive adjustment for ignition and mixture and describes the engine as excellent value for £8- 10s |

|

Sale of The Gerald Smith Collection

Following Gerald's death his radial engine was displayed for many years at the premises of TEE, Leamington and the other engines regularly featured at model engineering exhibitions. In 2005 the family took the decision to dispose of the entire collection and consigned them to the aero-engine sale at Gildings of Market Harborough.

|

|

A packed Saleroom eagerly awaited the sale of the Gerald Smith Collection of engines on 19th November 2005. Before this ‘once in a lifetime’ collection went under the hammer, 299 lots of more mundane engines were offered for sale. Following this there was a short pause whilst everyone geared up for the star lots, the Gerald Smith Collection. There had been a great deal of speculation about estimates and relative values, but the next few minutes would resolve these. |

First under the hammer was a ‘one off’ which went just over top estimate at £420. Three Magpies followed at £800, £980 and just £540 for a fan cooled marine version. Two Lapwings went cheaply and a third car model went just over estimate at £660. Four Redwings followed, with only the first making any real impact. It was obvious that there was not huge competition for these more standard models. The sole aero version of the Wizard did better getting up to £920 but the car version was knocked down for just £550.

Skylark number 1 produced a little more excitement getting up to £1400 but the marine version was below estimate at £820. So far the big hitters were keeping their powder dry although at least one bidder had showed his determination by sticking his paddle in the air and leaving it there. This seemed to work for him, as there was very limited competition.

To the final three lots. The Osprey 3 cylinder radial just struggled over estimate at £3600 with the Buzzard 5 cylinder radial going mid estimate at £3800. Now for the ‘biggy’, the eighteen cylinder double row radial. Estimated at only £5-7,000, how would it go? The general consensus was that £20,000 would not be out of the way and over £30,000 possible. A general air of expectancy filled the room as the auctioneer waited for the phone bidders to be contacted. Finally it was on offer and opened at £5000 on commission. Only two phone bidders did battle with the commissions and the floor. Was it to be a real bidding war? Slowly the price rose through the £10,000 mark with the inevitable slowness of phone bidding. And then there was just one phone bidder and one determined bidder in the room. Up in £500s to £12,500 and a pause, was this going to be it, but no another 500 and then another until £15,500 was reached. The phone bidder was offered it at £16,000 and declined bringing the hammer down to a round of applause and congratulations to the bidder in the room. Was he made to work for it, certainly? Did he get a bargain, only he can answer that.

|

Subsequently it has transpired that the engine had been disassembled at the time that Gerald's workshop was destroyed in an air-raid during WW2. Although he rebuilt the engine it is not known if all the internal components were complete or if the engine could be run. The current owner expressed the desire to see it running again but at present it is not known if this would be feasible. To some the results were a disappointment and to others refreshing. Gerald Smith’s engines are still at the top end of the market, but even the fact that they were from Gerald’s collection did not add a premium to the price, so they are still affordable. Maybe the numbers of engines on offer even depressed values? Right: The moment Mr Gilding's hammer falls on the sale of the Gerald Smith radial engine |

|

Gerald Smith's engines. The final chapter.

|

At the 2007 Leamington Model Engineering Exhibition, a superbly engineered seven-cylinder radial engine entered by John Scott-Scott, brought the story of Gerald Smith’s engines to a conclusion. Having produced the 3 cylinder Osprey and 5 cylinder Buzzard, Gerald had started work on a 7 cylinder version to be called the Kite. Much of the major machining of components had been completed when circumstances forced him to move from his house to a chalet bungalow. Although he had moved his workshop equipment to the new property, it was never installed and so the engine was not completed despite encouragement and offers to complete it on his behalf. He reasoned that if this had happened, it would not be a ‘Gerald Smith engine’ and he could not tolerate that thought. He had taken the finished components to Old Warden where the pieces were displayed, laid out on a coffee table, but that was as far as it got. Some while after his death his widow passed on the engine parts to John, who considered finishing it, but had reservations over Gerald’s vehement wish not to have a third party working on it. |

|

Some four or five years passed until early in 2006, when a conversation with a colleague persuaded John to complete the project. The drawings had long since gone, but in assisting the new owner of the Buzzard that was sold at Gildings in 2005 to get it running again, John was able to measure up the various components and make new drawings of the missing parts. Gerald had machined the crankcase, cylinders, heads, pistons, master rod and crankshaft, plus a few gears, sufficient to loosely assemble the engine. The remaining 282 parts, including reverse engineering of the fuel and ignition system had to be produced by John, and he began this task in October 2006. Conscious of Gerald’s thoughts about the engine, John had the push rod tubes, rocker covers and mounting ring beautifully anodised in a deep red and called the finished engine the ‘Red Kite’ so maintaining the origins, but reflecting his own substantial input. Looking at the quality of the engineering and detail finish of the engine on show, Gerald need not have had any reservations about John Scott-Scott completing the project.

|

|

|

On 22nd January 08 a starter was applied to the motor for the very first time, after two 'chuffs' it started and ran. When discussing this amazing piece of 'reverse engineering' with John, he revealed that this was not the only engine of Gerald's that he had rebuilt, kindly providing the photo's and text for this second engine, the Seagull.

|

This was a 12cc water-cooled 4 stroke engine based on one cylinder unit of Gerald's later radials, originally intended to be the subject of a series of articles for 'Engineering in Miniature', for readers to build at home from bar-stock. When Gerald moved house this engine was in bits in two meat trays. He never got round to reassembling it, by which time some parts had been lost. John therefore, with his widow's permission, undertook a complete rebuild, machining new parts where required. Having completed the rebuild John added that "We tested this in Gerald's garage, it ran smoothly but when we tried it with a 'rope' type dynamometer it was not very powerful. However, it would have sufficed for use in displacement hulls." It is now complete, and was for some time exhibited at 'The Fosse'. When that exhibition was removed, the family gave John the engine as a keepsake". ©copyright J Scott-Scott2006 Thanks to the late John Scott-Scott for providing the story of these projects and for additional photographs. |

|

Gerald Smith, gallery of discoveries.

|

|

|

|

Wizard car engine with box and instruction sheet from Miles Patience |

||

|

|

| Redwing in a Pioneer 2A chassis by the late Roger Howe | Battered Magpie rebuilt after a crash |

|

|

|

| Wizard from John Featonby | From Ken Smith comes this Lapwing build for horizontal mounting in a car, no lugs. | |

|

|

|

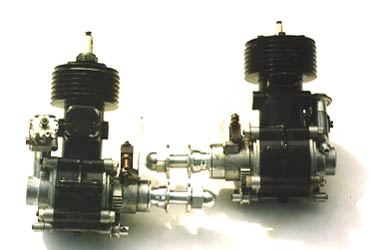

| Wizard from the late Ian Russell | Single and twin 'marine' Wizard motors built by Vernon Gray | |

Below can be seen the basic construction of Gerald's engines. Integral tank, centrifugal drum valve, lever operated advance/retard and the complex needle valve and venturi assembly. On the bottom of the NVA are two brass unions, one for the fuel tube from the tank and the other is for the earth connector via split plugs that he used for all the electrical connections.

|

|

| Lapwing components | Pair of Lapwings 1/4 & 3/8th plug versions |

And finally, nineteen years on from its original sale at Gildings, Gerald's five cylinder Buzzard was again for sale, seen at the Buckminster swapmeet and later advertised on OTW.

|

|

|

| Gerald's original mount and label | The Gerald Smith 'Buzzard' | Magneto & distributor |