|

Home Updates Hydros Cars Engines Contacts Links Contact On The Wire |

End of an Era

The Redfin

Project

Twinshaft Car and Motors

Confirmation that Alex is emigrating has brought an end to this ambitious project, responsible for getting many people on to the track that would otherwise have struggled to find engines and car parts. Alex took it upon himself to commission new engines and a basic car chassis, along with tyres to enable a beginner to get a car running at speeds equal to the best of the original twinshaft cars. As a final gesture, Alex donated all the remaining stock of tethered car parts to the Buckminster track for further fund raising. Without the Redfin project, there would be far fewer cars running at Buckminster. Thank you Alex.

The name of Redfin motors and the man behind the operation, Alex Phin, was already well established in the model aeroplane world for the range of retro motors he supplied. A while ago he commissioned a batch of new, retro, 2.5cc twinshaft diesels. This was similar in style to an Oliver Tiger but did not pretend to be a replica. It shared the same general layout with the flat mounting plate and cylinder axis angled up slightly. The crankcase is a super quality casting with the Redfin name and model name prominent. The internals are again not copies but those used in the immensely successful Parra motors. A peripheral jet venturi is another obvious departure although this could be changed for a 'curly' style one to allow the anticlockwise running that most commercial castings are arranged for. The quality of the Ukraine built motor is excellent throughout down to the dummy brake drums machined on to the inner hubs. These engines have been run successfully in a number of different styles of car, but after selling out two batches, there will be no more available, so it is down to a search of the second hand market.

|

|

|

| Alex with the new motor | Beautiful 2.5cc twinshaft | The box says it all |

Pre production prototypes of the Redfin car kit were allocated for comments on design and construction and Oliver Monk very quickly assembled and appraised his car as seen below whilst Steve Betney and John Goodall have spent a little longer to include delightful, scale bodywork. It is very many years since a kit of this nature has been available to tethered car enthusiasts.

Oliver Monk puts together the prototype

|

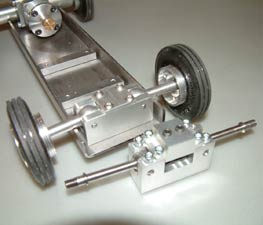

Alex Phin has sent me one of the first batch of four Redfin tether car chassis for me to have a look at. When I found out it was coming I ordered a twinshaft engine and shut-off to go with it. This is what came in the box, the main part of the chassis is steel as well as the tether arm. An adjustable front suspension unit with damping and the axles are steel. The tyres are test mouldings to prove the tooling, standard tyres will be black. The front wheel hubs are ball raced and complement the rear hubs that come as standard with the Redfin Twinshaft. |

|

|

This is the car all put together, it was an easy build all the parts are accurately made and nicely finished. I put it together on the kitchen table at a friends flat in Filey. One or two bits need a little modification but will be sorted for the main production run, along with a tank. Its going to be an ideal beginner’s car all it will require is a body to be made and it will be ready to run. The chassis will come with some drawings of suggested body shapes to give people an idea of where and how to proceed. Thanks to Oliver and Alex for this preview. |

|

Steve Betney completes his version

Another of the prototype chassis went to

Steve Betney who has built his up as this rather lovely Ferrari

Tipo 500 F2 car from 1952/53. A more detailed build article is

to follow when the final version of the chassis kit is

available.

|

|

|

John Goodall's Vanwall

John decided to incorporate a different design of front axle mounting on his

version in order to simplify the construction and provide further feedback to

Alex on this aspect of the design, which should be altered significantly on the

production chassis.

|

|

|

|

|

|

|

|

|

The Redfin twinshaft motor is providing power for a number of other car projects and restorations that we will feature as they are completed. One of the first was Oliver Monk's 'Car for Buckminster' based on a set of replica Oliver Mercedes castings, for which he provided a very detailed constructional article.

|

|

A Retro member has used a simple

plate chassis with damped front suspension similar to that in the Lev

Sprints Junior car kit The plate is milled from 8mm aluminium to allow

ground clearance with the correct sized tyres supplied by Alex. Converting your Redfin

'sneaker': Two new mounting holes must be drilled and tapped on what will be the

new underside if it is to be base mounted or on the plunger side if side

mounted. It could even now be mounted on the back of the tank as was often

the case. Nigel has offered to supply pre cut levers, so it is simply a

matter of tapping out the hole that previously held the wire, assembling and

fine tuning the hole for the plunger and then giving it all a good clean.

Remember though, the new cut off will now be handed and the plunger will

need to be set from the side of the car, either with it protruding or with a

'prodder' through a strategically placed hole in the side of the car.

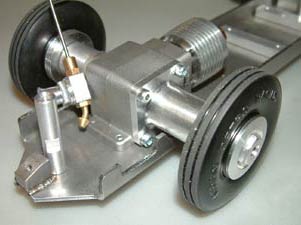

There has been a lot of problems with the 'sneaker'

type cut off as supplied, which is superbly engineered, but a bit too

sensitive, as push starts and minor bumps can trip it. To overcome this,

Nigel and Mike have turned the block on its side and added a lever that is

similar to those used on FEMA style cars for many years. Firstly, 2mm must

be machined off the underside of the block, where the recess for the plunger

is.

©copyrightOTW2020/2023